Mad River Distillers Whiskey Process

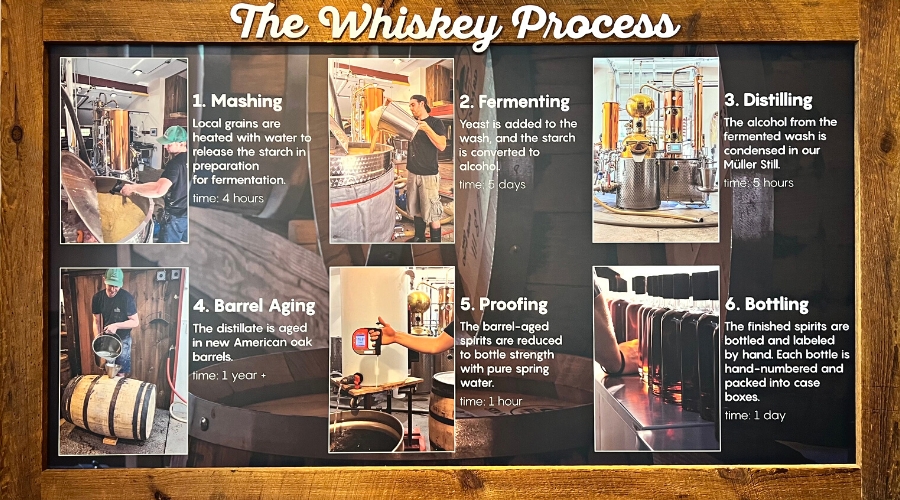

At our Burlington Tasting Room, customers often inquire about the whiskey making process. That’s why, if you visit us, you’ll find a framed overview hanging up on our back wall. There are six steps to making our whiskey, which includes mashing, fermenting, distilling, barrel aging, proofing and bottling. Here, we wanted to break down each of these distinct steps a little further, so you can better understand, and appreciate, your favorite whiskey.

Step 1: Mashing

To begin, we heat locally sourced grains in water. The hot water helps to break down the starch in the grain which allows enzymes in our malt to convert that starch into fermentable sugars. This process takes 4 or 5 hours. Our bourbon mash bill consists predominantly of corn, with smaller additions of malted barley, wheat and oats blended in. This special mash bill is what gives our Bourbon its deep and rich aroma of corn, smokiness on the palate, and a smooth aromatic finish.

Step 2: Fermenting

Next we begin the fermenting process, which takes 5 days. Yeast is added to the wash, and the sugars are converted to alcohol.

Step 3: Distilling

The fermented mash is then run through a 500 gallon pot still for the initial “stripping run” which concentrates the alcohol by volume (ABV) to about 50%, and takes roughly 5 hours. The final distillation is done on a smaller 60 gallon Muller Pot Still, which fine tunes the flavors and aromas. Bourbon is required to be distilled below a specific proof. We distill at no higher than 160 proof.

Step 4: Barrel Aging

The alcohol distillate is now ready for barrel aging in new charred American oak barrels for at least 1 year. Our Straight Bourbon is aged for 2 years.

Step 5: Proofing

Aged barrels are dumped and then filtered through a series of very fine cartridge filters. Once filtered, we reduce our barrel-aged whiskey to bottle strength with reverse osmosis (RO) water.

Step 6: Bottling

The finished whiskey is bottled and labeled by hand at our bottling facility. Each bottle is carefully hand-numbered and packaged, and then shipped out.

Now that you know a little more about our process, and the time and attention that goes into each bottle of our Vermont-made whiskey spirits, we hope that you’ll look for us the next time you purchase a bottle of American whiskey. You can find our whiskey (and other spirits) available for purchase online, at your local liquor store (including 802 Spirits locations throughout Vermont), and at our Tasting Rooms. We’re always here to answer any questions you have about our spirits and the process that went into making them. Cheers!